The fungi strains are carefully selected to grow Nordic Mushrooms which yield the greatest amounts of the compounds of interest. The fungi is inoculated on the most suitable birch sawdust substrate sourced from clean Finnish FSC certified forests at KÄÄPÄ Biotech or in supply partners’ facilities.

The fertile fungi grow in carefully regulated growing conditions and produce the most vital mushroom fruiting bodies. The fruiting body is the most potent part of the mushroom, rich in the compounds of interest. Only mushroom fruiting bodies are used to produce Nordic Mushroom extracts.

Quality control for indoor growing includes testing the raw materials (substrate) for contamination (heavy metals), controlled growing conditions (specific temperature, humidity, Co₂/O₂ and light), regular inspections of mushrooms as they grow and inspection for contamination during harvesting.

The mushroom fruiting bodies are placed into a dryer to ensure preservation of the compounds of interest. Mushrooms are then processed through a coarse grinder to prepare for extraction.

The industry-leading NordRelease® extraction technology is used to extract the full spectrum of bioactive compounds from each mushroom. Every species is treated with a unique method tailored to its specific compounds, ensuring maximum potency, purity, and bioavailability in every dose.

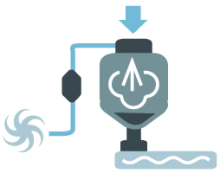

After extraction, the extract liquid is moved into a concentration tank where the liquid will be condensed. A specific density is required to produce our mushroom extract powders.

Freeze drying is a low temperature dehydration process that involves freezing the product, lowering pressure, then removing the ice by sublimation. This is in contrast to dehydration by most conventional methods that evaporate water using heat and results in the highest protection of the medicinal compounds.

Samples are sent to a 3rd party laboratory for bioactive compound levels as well as microbiological and heavy metal testing.

From the pure forests of Finland to the delivery of your products, we ensure premium quality raw materials, the highest standard of quality management and high-tech production and manufacturing methods. We are proud to deliver our Nordic mushrooms NordRelease® exstracts.